Small Business Mistakes and Failures to Avoid

In the decorated apparel and product decorator industries, it’s easy to make mistakes. That’s true of any business or your personal life. In hindsight, it all seems so obvious, but the real key is to look ahead and find out how to avoid mistakes and do it right next time. Here’s a list of the most common small business mistakes and failures for you to avoid:

Number 10: Weak leadership

Keeping a tight rein is important, whether you’re in the middle of the storm or things are going down Easy Street. Don’t be dictatorial, but keep things where they should be so you don’t have to crack down later. Give your employees clear direction on how they should behave. Is it OK to run the press while chatting on the cell phone? Can you check Facebook while on the clock? How about coming in “just a few minutes” after lunch? Write down your company policies and make a clear employee handbook out of them. These are the company standards you should hold everyone in the firm to. And most important: lead by example. Do what you preach, don’t just say it, and you’ll create the right culture in the company.

When you need to decide, be strong, think it out, and make the right choice. Everyone’s watching, so make the tough choices you need to so it doesn’t cause problems further down the road. Get advice – consult HR pros, lawyers, or a person advisor if you need to.

Number Nine: Nonstop Business

Don’t risk overworking yourself or your employees – that’s asking for mistakes caused by sheer exhaustion. In a small business, everyone has to wear several hats, so when things get busy, it pushes people hard. If you’re running a week or two of fourteen hour days, you’ll need to get help.

Don’t push your people over the edge – schedule 5-10 minute breaks throughout the day to recharge. Make being on the job fun too – urge your folks’ creativity, and laughter, have cookouts, bring in pizza and ice cream (not necessarily at the same time). Get your folks inspired!

Number Eight: Who are you?

One of the things that makes a decorated apparel company (or any company) great is they’ve found out who their core business target market is and they know how to reach them. The top shops only market to a few core types of customers, and everything else is icing on the cake. Be focused – you can’t appeal to everyone, and the attitude that you can is an invitation for randomness and failure.

Decide what one or two customers you should go after. Find the sweet spot – type of art, type of shirt, multiplied by this many pieces and locations. If that “perfect” order would work times 500 or 5,000, focus on that to cull and replace all those junk orders that are draining time and effort. Define who your ideal customers are, then go after them.

Number Seven: Marketing Mess-ups

Marketing is key, whether you’re wondering where the next order is coming from or the shop’s running around frantically to keep up with what you have in the hopper. One of the goals of good marketing, in fact, is to break the feast or famine cycle. You can’t do it after hours or in a few spare minutes on the job with a Facebook post or two – it takes time and effort. All this is closely tied to point number 8 above – you can only market well once you’ve determined who you’re marketing to, so invest the time to learn who they are and how to reach them.

Find out who your target market is, how they buy, and what appeals to them. Develop your method through doing your homework and a lot of trial and error. Refine and tweak your message, frequency and distribution channels. It’s a full-time, ongoing job and will need a good investment of time and possibly money.

Work your website, social media, blogging, and email list to reach your customers. Track what your customers are doing online – and what your competition’s doing. Find out who your strongest competitor is and what they’re doing right. Find out what channels they’re using – you don’t have to reinvent the wheel, just take your message out to the same channels your competition’s using.

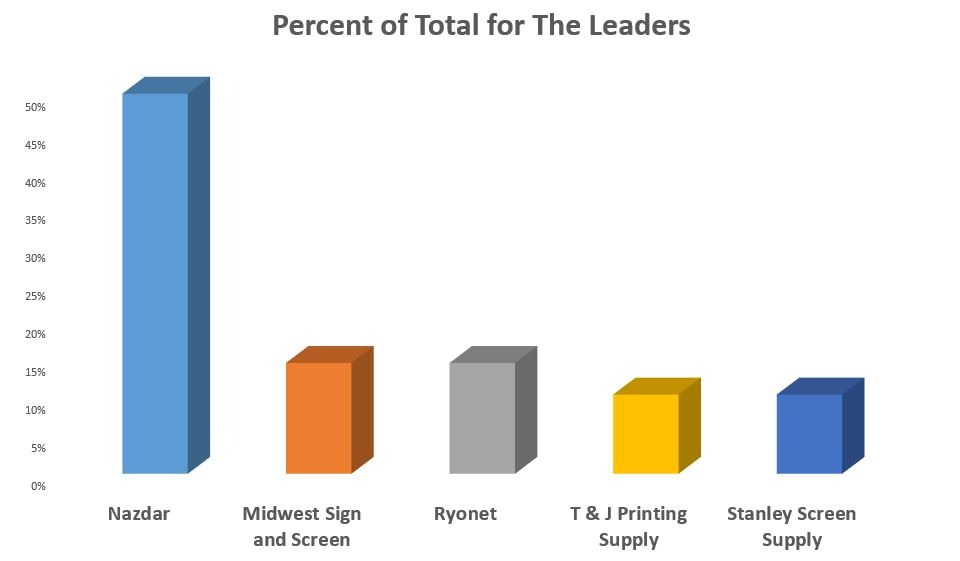

Number Six: Not knowing and understanding your competition

Keep tabs on the competition. What are they doing? Hiring, buying new equipment, redesigning their site, offering discounts? If you don’t you risk them taking a huge bite out of your business. Don’t copy their price list – just understand how they work, what problems they have, and anything else you can glean to stay ahead.

The key, though, is to define who your ideal customer is and what is critical to them. Fulfill their needs, and competition won’t matter. If you don’t keep up with your critical customers, your competition will eat out your business.

Number Five: Irresponsibility for Mistakes

Mistakes will happen. A misprinted color, UPS makes a mistake and the shirts won’t be there in time, you put the embroidery on the wrong sleeve. Whatever happened, what matters is what you do about it. Don’t try weaseling out of responsibility. Admit the mistake, make it right, and find a solution. The industry’s built on reputation and trust. Back your work and take care of your customers – you’ll build a large, loyal stable of clients, even if it’s financially painful or means working weekends and nights. And your reputation’s not just word-of-mouth anymore – the internet can make it so much faster to spread the good, the bad, or the ugly about you.

Number Four: Hey, how hard could it be?

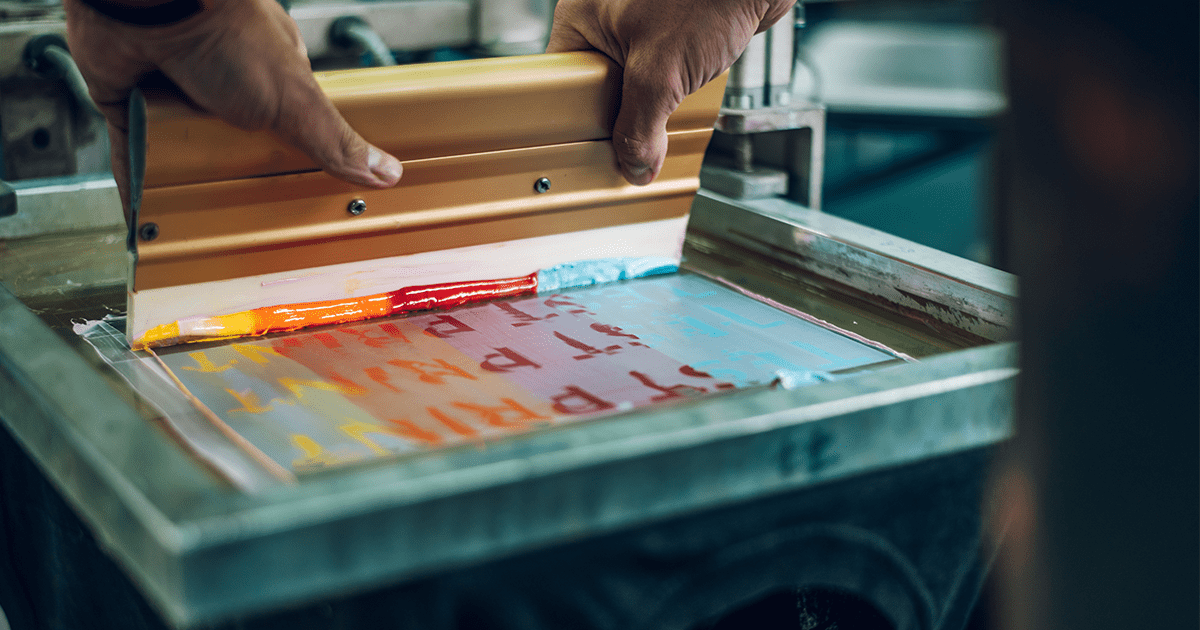

A word to startups – folks, this job ain’t easy. Printing or embroidering a shirt isn’t easy work. Just diving off the cliff, buying some equipment and trying to print or embroider goods is plain reckless. It’s incredibly hard for inexperienced people to understand how many steps there just to decorate a shirt. Regardless of whether the job calls for embroidery, digital printing or screen printing, the result is always a mix of craftsmanship, art and science.

So if you’re just starting out, get all the advice you can from the right people and do your research. Write a business plan, go to a trade show, take classes, talk to suppliers. Would you hire yourself? Know what you’re doing. “Fake it until you make it” won’t get you far.

Also, another few words for startups: think ahead and plan carefully. Write out a detailed business plan and put that learning mentioned above to good use. Make sure you have the startup capital you need to begin. Find out the best legal protections and know your taxes and tax write-offs. Start small and don’t overdo it.

Number Three: Financial irresponsibility

Keep your eye on the ball financially. Most shops fairly small and the owner is often the accountant too (and sales rep and customer service person and…and…) So who do you pay when you owe everyone? How did you get into the mess in the first place. If you don’t know how to do the books, hire or outsource them.

Just a bit of trouble can throw you off. You get a large order, the customer can’t or won’t pay on time and land in receivables. You still have to pay for the shirts and employees, not to mention ink or other supplies if you had to order them. Whatever you do, don’t leave bills or employees unpaid. Once you get that reputation, it’s hard to get that trust back.

Number Two: Cutting Prices

When times get tough, many shops drop their prices to try to stay in business. Trouble is, once you treat your hard work as a commodity, your customers will expect that low price from then on. Don’t be foolish. Say no to people or demands if they make the order not make financial sense. In some shops, half their jobs don’t make any money for them. Just staying busy doesn’t mean you’re profitable. Find out what the costs of doing business are (labor, materials, and overhead) and setting a goal for how much money you need to make based on those numbers is how to build a price list.

Figure it out. What does it cost you to print or embroider something? Are you giving free screens, digitizing or other stuff away? How much is that really costing you? Could you be charging for that? Many shops charge for those plus art, rush jobs, bagging, drop-ships, and fulfillment or whatever tasks are on the order. You could be missing a giant pile of money on the table.

So it is it better to be moderately busy with highly profitable work, or insanely busy with work that barely pays you anything?

Numero One: The Inexcusable

What’s the biggest blunder? It’s often the owners not understanding the business and getting in over their head. The main issue? You, the owner, have to be there on the floor and understand what your employees have to deal with, not just sit in an office and look at balance sheets.

You must understand the nuts and bolts of the business to succeed. You have to know what it’s like to set up and print a three location, 5 color per side order for 85 shirts or change a thread color for every shirt in a 500 piece order. Oh–and the both jobs must ship today. Talk to the people who do the work and understand their effort, stress and pain points.

Whatever the size of the operation, company leaders control the firm’s culture, how things work, and the standards of operation. Even with a good management team, it can all fall apart if the owners aren’t committed to and present in the business, as the owners will make financial or policy decisions based, not on reality, but on tunnel vision and the need to extract money from the company. Short-term thinking seldom produces long-term positive results.

Have clear expectations. Ready, Aim, then Fire – don’t shoot from the hip first and ask questions later. Let your employees know what they’re aiming at and keeping clear, constant communication open is key. If the shop’s busy but there isn’t the expected ROI, and the owners aren’t happy but don’t communicate, well – that’s why shops go out of business and used equipment dealers always have a full inventory of items to sell.

So avoid these pitfalls and build up your business. Enjoy the ride!