Hi, everyone. This is Jay from ShopWorks and in this OnSite NXT preview video, we’re going to look at designs. And we’re going to contrast how designs are handled in the current OnSite system and how they’re going to be handled in OnSite NXT.

In the current OnSite system, the concept of designs is a little quirky. And our goal for OnSite NXT was to kind of eliminate those quirkiness, little quirky things. We’ll talk about those in a minute, and to improve and simplify the entire design system, and of course make it more powerful as well.

And let’s start by talking about some of those quirky things, and then we’ll kind of show you. I’ll do some demo and show you how we handle design and OnSite, current, and how we will handle it in OnSite NXT.

So, the number one point here is a design in the current OnSite can mean different things. It can be a single design location, or it can be in multiple design locations. This is confusing to users, especially new ShopWorks customers.

Most people tend to think of a design as a single thing, as opposed to a collection of things. The second point here is in the current OnSite, there are designs and then there are order designs.

And as you know, these can be different for a given design number; the order design can be different from the actual design master design. And this requires that if you want to, the designs have to be synced. This does add some flexibility to the system, but in general, we found that it’s confusing.

And if you don’t manage it properly, it can cause mistakes on orders. So, we’ve kind of revamped how that’s done.

And that second point leads to our third point. Because there are multiple places to manage a design, being on the master design and then on the orders, as well. There are multiple places to manage the design, whether it’s done or not, what it looks like, print locations or embellishment locations.

All of those can be managed from the design section and possibly also on an order. So that is not an ideal situation.

And that’s going to be changed here in OnSite NXT. But before we get to OnSite NXT, let’s kind of look at the current OnSite.

So, I’m flipping over here to OnSite, and we’re already in our design section.

And we’re going to look at DC Special Olympics.

As I’ve done in previous demos, this is a saved customer that we do a lot of business with in our fictional world of running an embellishment shop. And we’re going to look at our torch run 2024.

So, in the current OnSite, you can see this is a single design number twenty eleven. And that design number has two different locations, a full front, and a full back.

Three colors on each. I’m not going to get into the details of this. There are custom fields.

You know, as a current user, whether it’s screen printing or embroidery or promotional products or whatever defines how this is going to look. They can look a little bit different based on the design type in the current OnSite.

And so, this is what we call the master design or the key design. This is the source data of the design line.

Now if we go over to our sales department, let’s bring up our DC Special Olympics orders.

And I’m going to go down here to the tour, an order that has tour 2024 on it.

And if I go to the design here, this is the same design that we had in our design section. However, there are certain settings that control this, so you do have some control, but I can make one-time changes to the design right from here. So, let’s say, for example, on this particular order, the customer only wanted the front print. They didn’t want the back print. Well, I can just eliminate the back.

Now what’s the problem with that? That seems pretty flexible. It is flexible, but there are some problems with it. Problem number one is it’s the same design number.

So, people on your shop floor could get confused on an order. They could just read the design number and pull the design, and they would see the films for that design. Let’s say you’re using films.

And then they would say, oh, well, it’s a front put it in a back they might ignore the paperwork or this computer system, and they might actually print the front and the back accidentally. So, the fact that it’s the same design number, but actually a different configuration.

Although it’s flexible, it can introduce errors into your shop. The other thing is colors can be changed. Things can be changed. So, on this particular order, they want to add, or maybe they would add another location, which is a name drop.

So, there’s lots of flexibility to it, but that flexibility can inadvertently introduce errors, into your printing or embroidering or whatever kind of embellishment you’re doing. I tend to show these examples from a screen printing because that’s my background, more screen-printing embroidery, but everything I’m telling you applies no matter what kind of embellishment you’re doing.

So that kind of requires we really have a separate design. It’s the same design number, twenty eleven, but it’s really produced separately. So again, that’s kind of a problem. There are some potential benefits to it, but there’s also some problems with it. And we’re from what we see with customers, there’s more problems than benefits.

Now we have some other concepts in the system like design variations, which is a way around this, where you can create a variation of a design. And then force your users to use the variation. But all this requires procedural stuff on your end that you understand our system, how it works, and that you know, procedurally, you create your own procedures.

So that’s kind of the disconnect between the designs and order designs.

Also, the status is different. So, if I go into my production portion of OnSite, and I changed the design status of this, I have to push that design change to the master design. The same is true, the opposite direction.

If I go into designs and I go to production, I can see which orders this is being used on, and I can update those orders with this master design information if I want to, or I can do the reverse. I can go to the order and push the order changes to the design.

And there’s no rules to this. It can be done, you know, so again, that requires procedural stuff on your end to make sure things don’t get screwed up, etcetera, etcetera. So, one of our key things with OnSite NXT is we wanted to find a way to simplify this.

So, I’m going to close this down.

And let’s go over here to our OnSite. So, this is OnSite NXT. And if you watched the video on the UI UX user interface, user experience, you know that it’s more floating windows and multiple windows and stuff like that. So, this is my main app, if you will, the ShopWorks app or OnSite NXT app. And I’m going to go to designs, and it’s going to take me to my design’s main menu.

And I’m going to bring up all my torch run designs and you can see there’s our different designs. Now the first thing I want you to know is that designs in OnSite NXT are single design location only. So, we’re eliminating the ability to have multiple design locations on a design. Now that sounds horrible.

When I tell you that, you’re like, oh, that’s huge functionality. Well, most of our designs are multi location. I’m going to show you how we’re going to handle it in OnSite NXT. But it eliminates the confusion of, a single design meaning multiple locations.

So, if you only want to print one location, then you’re just going to select the one location. So, let’s kind of just continue with this thought process a little bit, and this will make more sense.

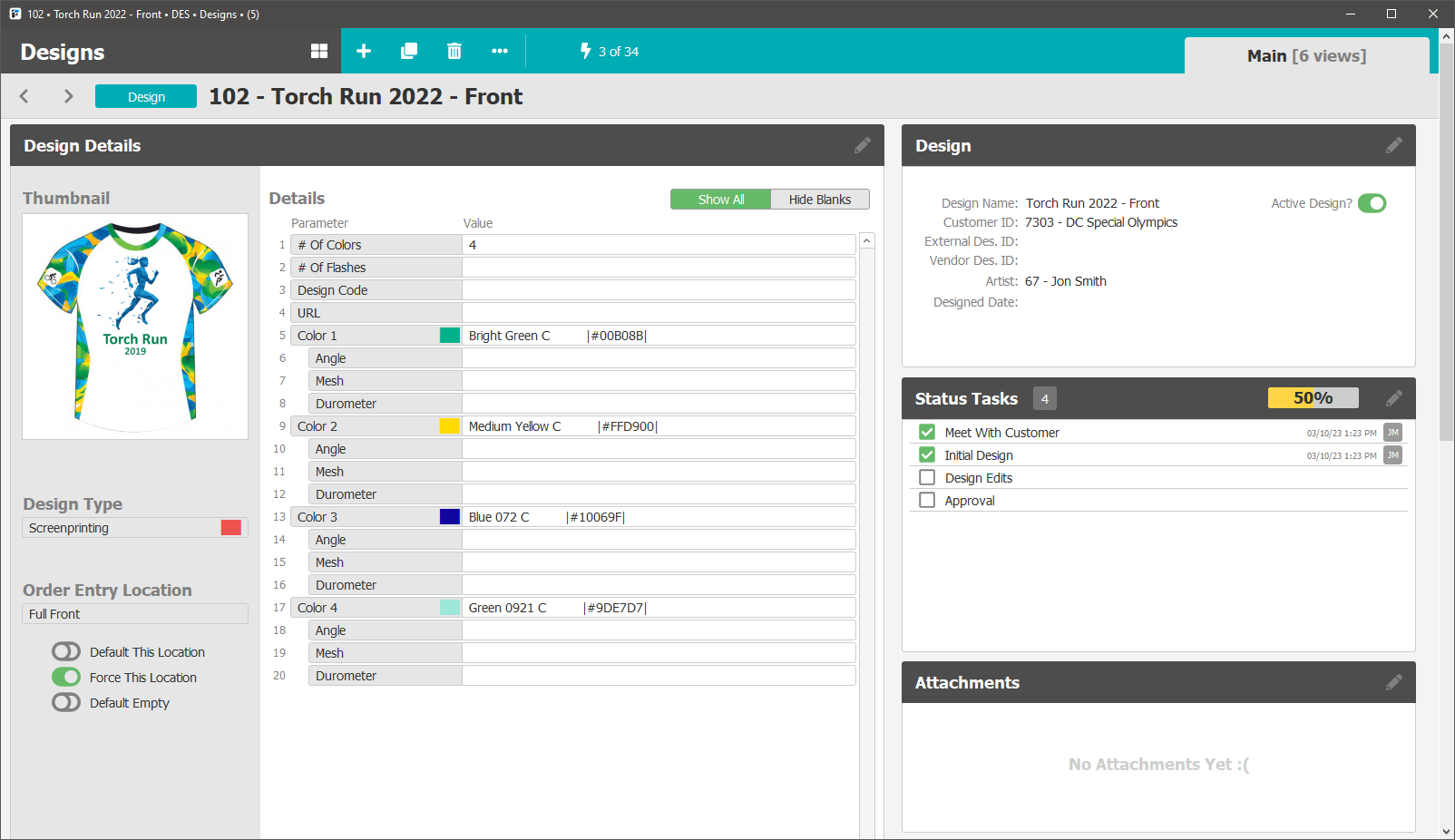

So, I can see here my designs, I have design ID one zero two and design ID one zero three. And if I click on one of those, it’s going to open up. There’s the front. And if I want to, I can open up. There’s the back. And because we’re, you know, using a large monitor here, and I have multiple windows, there is some consideration for Windows management that’s covered in, you know, you can get a crazy amount of windows going on here. So, I don’t have to open up these windows, but it’s nice because I can put them side by side here. I can minimize that window. And now I have my two designs locations, right next to each other.

So again, here’s my full front and full back of this design. Same as we did in the old system, but instead of being one design, it’s two designs. I want you to just notice a couple things here.

The details, every design is going to be parameter based. What does that mean? Well, what that means is in your current OnSite system, there are certain design configurations. You have a screen print design configuration, embroidery design configuration, and that kind of hard wires how many custom fields you have, the look of the fields, and all that sort of thing.

Well, we’ve made that much more flexible in OnSite NXT. Every design, you define what’s in that design. So, every design type, we still have the concept of design types. So, you can see your screen printing. You can have embroidery, you can have promotional products, awards, whatever you want.

You can have as many different design types as you want. But instead of you having to use our ShopWorks hard wired design configurations, you don’t have to do that anymore. You can go down as far as you want.

So, it’s not a horizontal grid anymore. It’s just vertical information. But the value of that is it allows you to create as many different colors as you want as there’s no limitation on colors. There’s no limitation on number of parameters.

You have a lot more flexibility in the system. Now remember, this is just a preview video. So, I’m just kind of previewing things for you. As we get closer to release, we will have actual more in-depth training videos for you. So, I’m not going to go into everything in these videos. I’m just kind of giving you a taste of what we’re doing here.

Now a couple other things I’d like you to notice, there’s a there’s tasks associated with a design. And as those tasks are clicked off, it stamps who did it, and it updates the percentage.

We have attachments, and I’m going to give you a little teaser for the future because I’m going to do some more of these videos. We have some additional concepts we’re introducing for OnSite NXT, and a huge one is “tickets”. So, “tickets” is going to really help you with your workflow.

Queuing and workflow and knowing when things are done and getting things done, tickets, and queues are going to be concepts. We’ll introduce those in another video. But you can see here there’s tickets, meaning work that needs to be done associated with this particular design.

Of course, you have attachments, you have a thumbnail image, click on the thumbnail image, you get a zoom just like you did before.

Now the other thing I want you to notice here is collections.

So that’s kind of a new concept we’re introducing in OnSite NXT. So, let’s just kind of make these windows go away here.

And let’s go back over to our main, designs window.

And instead of designs, I want to look at design collections.

So, design collections let’s look at all my active design collections.

Let’s go back to collections.

We have an error here, so remember this is in development; still lots of glitches to iron out.

Let’s go back to our design collections.

And let’s just bring up all of our design collections. So, if I go to design collections, I can see one called torch Run shirts 2022. Now what is that? Well, if I go to it, this is a collection of multiple design locations.

So, this is how we’re going to handle multiple design locations in OnSite NXT. And there’s a lot of power in this because, one of the things that you can’t do in your current OnSite is you can’t have a design that has multiple embellishment types on it that still true in OnSite NXT, but a design collection can have multiple embellishment types. So, for example, if I had a screen printed front, or screen printed back, let’s say, in an embroidered front, I could have a design collection that would allow me to have that have screen printing. I can have embroidery.

I can have whatever I want on there. And the power of that is that when someone goes to order entry, and there’s they don’t they can select individual design locations, or they can select the entire design collection. And in this case, you know, we have a shirt that’s a front and a back. So, the user would select from the collection, and it would select all those items.

Now we’ll get into that more when we get into the, like, how order entry is done. We’ll illustrate that for you. I’m not going to show you that in this video. However, just kind of that’s where we’re going with this.

So, when someone is a user and they’re going to select a design for an order, they can either select from an individual design location or they can select from a design collection. And as I mentioned, the design collections could have multiple embellishment types in it, so that is very powerful.

Alright. So, what are our key takeaways on designs?

Well, let’s start at the top. All designs are parameter based. And what that means is you get to define what every design is and how it works. There’s usually going to be a lot more power, a lot more flexibility in how designs are configured in the system. All designs are going to be single location only. Now, that means there’s a lot of simplification.

When a design’s done in OnSite NXT, let’s go over here to a design. When a design’s done and OnSite NXT, it’s done everywhere. It’s done on every order. There’s no more having to sync between order designs and the master design.

There’s only a design. That’s it. Now we still have concepts of and again, I’m not showing you this here in this particular video, but you’re still going to have design variations So, for example, we have a one-time change that a customer wants to do to this particular design. Well, you’re going to create a design variation of this design.

You’re going to make your changes, and that’s what’s going to be used on the order. And that’s going to help eliminate problems on orders, miscommunication, because a design in the new system, a design is a design is a design. If you want to make a different design or a variation of a design, you can do that. But the design is what the design is in the new OnSite NXT.

They’re all single location only, as I mentioned, and the additional power that we’re going to add to that single location only because it does take away some functionality is that we have design collections, so design collections are going to allow you to combine these designs together into collections.

And that’s going to handle cases where you want multiple locations.

And the last new concept is there are no more order designs. We’re eliminating that it was causing more problems and confusion than solutions.

So, if you do want changes to a design, it’s going to require a new design or a new variation.

Now I know some ShopWorks customers might not like that.

Because it is taking away some flexibility.

However, we think procedurally. It’s just a better way to do it.

And it’s going to eliminate more problems than benefits. So that’s what we’re going with for OnSite NXT.

Alright. Well, thanks for your time. This video is coming to a conclusion. We’ll have more coming soon. More previews. We’ll get into the new tickets and, queues that I mentioned. That’s a cool new feature.

Workflow is really cool in the new OnSite NXT to be better workflow.

Allows you to know what’s going on with your business.

So, we have a lot more to show you. Those will be coming in more videos. So, keep your eyes peeled for the next preview video. Thank you.

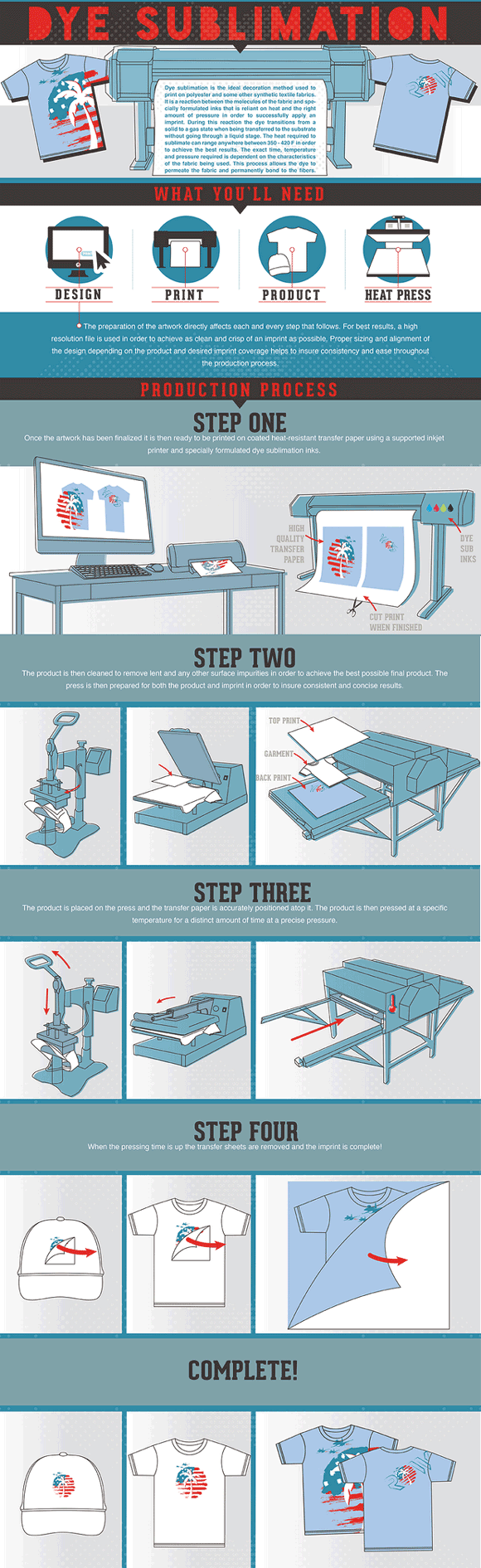

To start off, let’s discuss what heat transfer is. Heat transfer is the process of applying an ink-based design (usually one printed on a sheet of special transfer paper) to the product to be decorated (usually a t-shirt) with a heat press machine. As the name implies, a heat press machine works by using heat and pressure to apply the design to the garment.

To start off, let’s discuss what heat transfer is. Heat transfer is the process of applying an ink-based design (usually one printed on a sheet of special transfer paper) to the product to be decorated (usually a t-shirt) with a heat press machine. As the name implies, a heat press machine works by using heat and pressure to apply the design to the garment.