Machines for screen printing form a vital part of the process in this industry. They help to produce a great variety of products, starting with apparel and ending with promotional articles. Key equipment includes but is not limited to, screen printing presses, dryers, flash units, and flat stock printers.

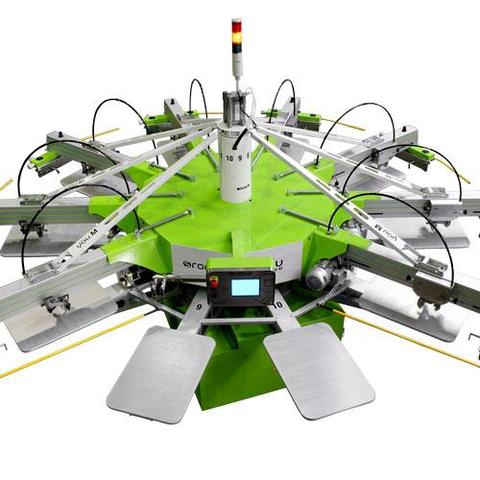

Screen printing presses, which are the industry workhorse, transfer the ink through a mesh screen onto substrates. While manual presses are great for limited runs, certainly for high volume, one of the best options is to utilize an automatic press. These machines come in various sizes and configurations to accommodate different print jobs, from single-color designs to complex multi-color prints.

Besides the presses, there are the dryers that are very important in the ink drying process. A flash cure unit partially dries the ink for the subsequent print passes, while the tunnel dryers complete the process. Other peripheral equipment, like exposure units for screen creation, reclaim tanks that recover inks, and conveyor systems, optimize the whole workflow of screen printing.

Screen Printing on Apparel

This is the most renowned and versatile process of screen printing on apparel among methods of garment decoration. The process initiates with a screen mesh stencil in the exact shape intended for an image to be made. Next is the placement of the screen onto the garment, whereby ink is forced through the mesh onto the garment, creating the design by using a squeegee.

Screen Printing for Flat Stock

Other areas where screen printing can be applied include flat surfaces like posters, banners, and signs. The process is the same as that for apparel printing, but it calls for a flatbed press, a large machine specially made to hold flat substrates.

Additional Equipment

In addition to presses, dryers, and flash units, many other pieces of equipment are involved in the screen printing process. These include exposure units for creating the mesh stencils for the screens, and reclaim tanks, in which the mesh is cleaned of ink so that it may be used again. Conveyor systems are often put into use to move garments through the printing/drying process.

Software Integration

Machinery depends on factors such as the amount of your production, the complexity of your print jobs, and the budget. With the proper machinery, screen printers can create high-quality prints more effectively not only for apparel but also for point-of-sale applications like T-shirts, bags, hats, and even promotional items.

This is where software, like ShopWorks OnSite, can be used to capture metrics on how these machines perform daily. This will build an effective way of tracking production, spotting bottlenecks, and optimizing the whole workflow. https://shopworks.com

When this software is integrated with the machinery, it can offer valuable insights for screen printers to make data-driven decisions that bring about increased efficiency and profitability in their operations.