What To Look For When Buying Used Screen Printing Equipment

Tips On Buying Used Screen-Printing Machines and Equipment

In many small and medium-sized businesses, especially if you are a screen-printing startup, one of the finite resources is cash. Hence, opting for used screen-printing equipment is one of the best decisions you will ever make. This is because you will end up saving a lot of money while getting yourself equipment that meets your business needs.

However, most screen-printing startups shy away from buying used screen-printing machines and equipment. The primary reason for this is due to their fear of procuring an overly used or malfunctioning piece of equipment.

It is true that purchasing used items or machines poses a lot of risks, especially if you don’t know or have enough experience to discern which tool is in excellent working condition and which one is not.

Nevertheless, in this article, you will learn the steps to take and what to look out for when buying used screen-printing equipment.

Why Do I Need to Purchase Used Screen-Printing Equipment?

There are usually a lot of expenses to contend with when starting a new screen-printing business. This includes the cost of renting a suitable office or space for operations, annual running costs, electricity bills, etc. The cost of the equipment is not left out, as well.

However, you can cut down the cost of starting your dream business by purchasing used screen-printing machines. Many startups usually find this aspect a bit challenging.

While buying new equipment is faster and easier, the truth is that if you can lay your hands on quality used screen-printing equipment that is in excellent condition, you will enjoy roughly the same value at a much lower cost. It is also the preferred course of action since you are likely on a very tight budget as a startup.

However, securing properly used equipment is a challenge on its own. Not only is it wrong to start a new business with faulty machines or equipment, but it can also reduce product quality, efficiency, as well as effectiveness.

This will, of course, eventually affect business cash flow, and before you know it, you are out of business even before you start.

A veteran in the screen-printing business has enough experience under his or her belt when it comes to buying used screen-printing machines. And since you are a novice in the industry, it is highly unlikely for you to have such a wealth of experience behind you.

This is why you must learn what to keep your eyes peeled for when searching for reliable used screen-printing equipment.

What Should I Look Out for In Used Screen-Printing Hardware?

Keep the following tips in mind when searching for used printing equipment:

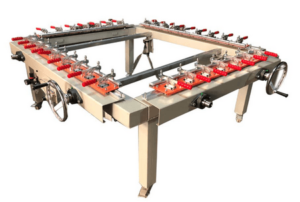

Static Screens

You can readily come across Static Screens, which are part of the components of a screen-printing machine. So, take a close look at the mesh, which must be in a usable condition. If it is not in perfect working condition, you should ask for a replacement immediately.

It is much better, and economically cheaper, to replace the mesh than to buy an entirely new Static Screen.

You should also check the screen tension to be sure that it has not deteriorated. If it has, then check to see whether or not it is firm enough to facilitate smooth production.

Otherwise, get a new one or look for another source of supply.

Electric Dryers

Electric dryers are one of the most common items that are usually left behind by printing shops that want to relocate. And it is understandable because most dryers take up a lot of space.

The real challenge, however, is that dryers require a lot of power to operate and must also be well-ventilated for smooth operation.

Buying used electric dryers, in most cases, is usually pointless unless the machine has barely been used. But if you must purchase it, make sure that all the electric fittings are in excellent condition.

Check the equipment out thoroughly, and take an expert along with you for added measure. This is to be sure that the electric fittings do not have any unattended faults so that they will not cause a hazard in any way at your business location.

Plastisol Ink

As long as plastisol is stored correctly, it does not spoil or expire. It is also one of the common items that closing or relocating shops usually leaves behind.

However, it is better to stick with full containers since half-filled containers may have been contaminated as a result of the addition of external components.

Flash Cure Units

Check the bulbs of the flash care units to ensure that some or all are not damaged. If they are, then replace the damaged one. This will help you to save a lot of money instead of purchasing a brand-new flash cure.

Platens

When platens are purchased secondhand, they come at a much lower price, up to 50 percent off the original price. That is a lot of money that you can channel to other purposes.

Moreover, they work almost as efficiently as brand-new ones. But check to make sure the used platens you want to purchase are not warped in any way.

Where Can I Find the Best High-quality Used Screen-Printing Equipment?

The first step to securing used equipment is to know where to look. Printing equipment is usually manufactured or designed to outlast the business of the original owners.

And if something unexpected happens and the owner goes out of business, these screen-printing tools are sold off at meager prices. This is why you should position yourself as a smart businessman who will see and take advantage of such an opportunity without wasting any time.

You can find used screen-printing equipment in excellent working conditions via the following channels:

Online Shops

There are a plethora of online auction platforms out there where you can find owners who are more than ready to sell off their used screen-printing machines and equipment.

Some of these online platforms include:

- CraigsList – remarkable and serves different niches. Therefore, make sure you bookmark the website and visit it as often as possible. Always check urban and metro areas nearby if you can’t find what you are looking for in your city.

- The Facebook Marketplace – allows you to find great deals near you quickly.

- eBay – always has something that users want at incredibly low prices.

However, the best place to buy old screen-printing hardware is from specialist sites such as:

- Cosmexgraphics: You can purchase used equipment at very moderate prices here

- DigitSmith: This is the go-to resource for people who need to use gear in the embroidery and screen-printing industry. The deals in this forum are unbeatable, even though it is old school.

- Screenprinting Products: For used, high-end screen-printing equipment at rock bottom or reduced prices, this is the place to visit. Dave McLain runs it.

When you catch sight of the old screen printing equipment you are interested in, you should ask as many questions as possible. Questions such as:

- Why are the screen-printing machines being sold?

- What is the usage period of these machines?

- What is the frequency of use, or how frequently were these machines operational?

- Are there any previous or existing faults that you need to learn about?

Since the transaction is likely to take place online, insist on getting comprehensive and highly detailed or high-definition pictures of the fundamental parts of the equipment.

It will also be in your best interest to see or observe the equipment when it is in operation.

The second-best line of action you should consider is to hire an experienced or veteran screen printer while making the purchase. This is to significantly reduce the risk of finishing up with a machine that conks out while in use.

Relocating Manufacturers or Shops

Shops can relocate for several reasons, and printing shops are not an exception. Some of these printing shops may want to part with some of their old screen-printing equipment to minimize the cost of transporting them to the new location.

Some manufacturers may also want to get rid of some machines so that they can shift their focus into producing other types or upgrading to new ones. This usually drives such manufacturers or relocating printing shop owners to sell off the old stock or equipment they do not want to haul off in flash sales.

In this scenario, however, you may even be lucky to get your hands on brand-new screen printing equipment at a ridiculously low price.

Closing Shops

Just as relocating, screen-printing shops close down for a variety of reasons. One thing you can be sure of is that malfunctioning screen-printing machines are seldom the reason why businesses shut down unceremoniously.

Most screen-printing equipment lasts much longer than the majority of the businesses out there. This is because they are intricately constructed to last for extended periods, which is why the new ones are costly in the first instance.

So, if you hear that a screen-printing shop in your locality or the next town is closing down, run as fast as possible to the location.

If the shop that is closing or relocating is a big one, then the better for you. This is because you will be able to get the best deals since they will have a lot of machines that they’d like to get rid of immediately.

Do not wait until such shops list the fact that they want to sell their equipment online before you visit them. You may lose out on excellent deals that way. Besides, there are several pieces of printing equipment that they may forget to add to the list.

Therefore, always be on the lookout for closing shops so that you can get your hands on the readily affordable equipment they want to sell off.

Liquidation Outlets

Almost every urban center has one or more large liquidators for office supplies and furniture. People who run these outlets are privy to information about closing shops, etc.

So, get close to such individuals, let them know that you are interested in purchasing equipment, and always stay in touch. Guess who will come up first in their minds when they eventually have access to some screen-printing machines? You, of course!

On a final note for this section, broaden your horizons. Do not let your search be limited to within your city. You may even come across some excellent and unbeatable deals in a city that is far away from your place of residence.

What are the Used Screen-Printing Machines, Tools, and Supplies You Can Buy?

Here are some of the used screen-printing tools that you can purchase at significant discounts:

Static Screens

This is perhaps one of the most efficient and best ways to save a lot of money as a beginner or startup in the screen printing industry. You can find used screens with usable mesh at $2 to $5 max.

You can also re-mesh your used screen much later on, and it won’t cost you more than $10 to replace each one.

Electric Dryers

Electric dryers are usually big, so most relocating shops are not always interested in transporting them to new locations.

But if you are interested and willing to hire a box truck to move it to your shop, you will surprisingly discover how extremely cheap they can be if you buy the used version.

So, you should look at spending not less than $1,500 to cover the cost of purchase and transportation. You need to make sure, beforehand, that your shop is equipped with the 3-phase requirements as well as ventilation that these dryers require for efficient and smooth operation.

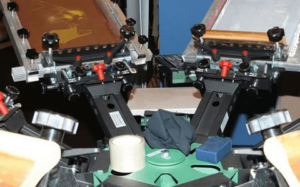

Automatic Press Squeegee Blade Holders

The retail prices of squeegee holders cost around $70 each. That is a lot of money, considering the fact that you can purchase the used variety at $0.50 per inch; that is about $8 for every 16-inch squeegee blade holder. An 85 percent discount looks good in the books, wouldn’t you say?

You may be lucky enough to come across oversized flood bars and squeegee blade holders at eBay or a brick-and-mortar outlet. All you need to do is to whip out your miter saw and cut them down to the required sizes!

Plastisol Ink

Plastisol can virtually last forever, provided it is stored correctly since it does not have any expiration date. Make sure you go for full containers as some users may likely add in some external components – such as a reducer – to half-full containers of plastisol.

Flash Cure Units

Do you know that, with in-depth research, you can find a flash cure unit for as low as $1,400? It doesn’t even matter if you have to replace a few missing bulbs, which usually cost approximately $100 each.

That is still way less than forking out $2,500 to $3,000 for a brand-new flash cure unit!

Stock Ink and Pantone Matched Ink

Many veteran screen-printing shop owners can tell you for free that you can purchase stock ink at incredibly steep discounts. More so, some shops usually give out Pantone-matched ink, free of charge. Nevertheless, you need to be aware that to dispose of uncured Plastisol ink, you have to follow local regulations about hazardous materials.

Can you think of a way to put the ink to good use? Then, it is a smooth win for you.

Platens

You should know by now how extremely expensive brand-new Platens can be. Therefore, you really have no choice but to buy the used version if you are looking to cut costs.

You need only to confirm that they are not warped in any way by going over every inch carefully or bringing an expert along.

Used platens cost way less – up to 50 percent – than brand-new versions. And the good news is that they work as efficiently as a new set.

Exposure Units

Finding used exposure units that are in excellent shape is very tricky, but not impossible. This is why you need to perform a lot of research if you truly need them.

Depending on the model you are looking for, most used exposure units cost between $700 to $3,000. This may not seem like an excellent bargain to you, but you will thank your stars if you land an exposure unit that serves you for a very long time.

Additional Pointers for Saving on Furniture, Production Shelving, Racks, etc.

As mentioned earlier in the opening section of this article, opening a new shop for a screen-printing business can cost you a lot of money. If you are on a tight budget, then you should consider getting the used versions of most of your office paraphernalia.

For instance, brand-new filing cabinets, desks, office chairs, shelving storage racks, tables, etc. come at hefty prices that will dent your wallet or bank account.

And since most of the furniture will likely take a lot of beating anyway – ink stains, scratches, etc. – then consider getting something that is low-cost and very replaceable. It is not as if you will be vying for an office design award, anyway.

Once again, a visit to the local furniture liquidators in your area will pay a lot of dividends, especially if you befriend them well. You should also be on the lookout for business closures or large relocations in your area so that you can swoop in to snatch up any furniture they will not need again.

And do not fail to take note of estate sales, garage sales, and even moving sales. Since most furnishings for your printing shop – such as bookcases, wire shelving, chairs, and desks provide little direct production value – getting them at steep discounts will save you a lot of money.

Hot Tip: If you want to get the best deals at estate sales, go on the very last day of the auction!

You can get the following at great discounts:

- Wire racks and shelving: You will be astonished to discover that you can purchase nice-looking shelves at $10 each, especially if it were at an estate sale (remember the tip shared previously). Since no one else wants them, you can pick them up along with wire racks at low prices.

- Clothing racks: You can get these for virtually free if you are lucky enough to come across department stores that are relocating or have gone out of business.

- Pushcarts: Every shop must have industrial-grade pushcarts. Unfortunately, they are astonishingly expensive if you go for new ones. But you can find excellent bargains – between $20 to $40 – for used carts if you spend quality time online.

- Pallet racking: A new 8-foot pallet rack can cost as much as $350! That is a crying shame and a total waste of good money because you can get the 64 linear feet version – which comes with shelving – for about $600 at a moving sale.

Conclusion

As you can see, you can save a lot of money when starting out as a new screen-printing business owner.

Even though every screen-printing shop is remarkably different, one thing is sure:

It is, therefore, a wise move on your part if you can take advantage of these low prices and secure these great used machines for your business. Business is all about profit, and if you can get well-conditioned screen printing hardware, you will not only save a lot of money but also enjoy the extra profit.

Therefore, carry out a lot of research; ask probing questions, make inquiries, and test a lot of screen-printing tools. You should also be very good at negotiating prices.

Always be on the lookout for new deals; keep up with your competitors, and the goings-on in the industry. You will soon start smiling to the bank every day of the week when your screen-printing business picks up!

Learn about The Equipment Needed for a T-Shirt Business.